The Stiffest Steel Tube Chassis in CMR EV History

2022

For our 2023 car, one system that I took on was the chassis system. This system was heavily involved with all other vehicle systems, due to spaceclaim and driver ergonomics. As a result, this was not only a technically challenging system to design but had also become a communications challenge amongst a team of 30+ engineers all vying for more room in the car

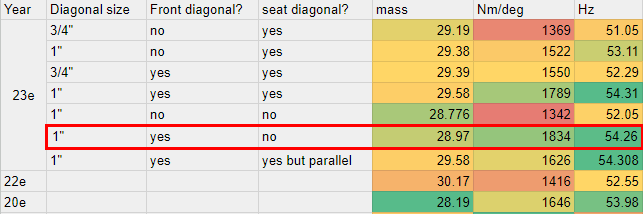

Apart from spaceclaim, I focused on making the chassis as light, small, and torsionally stiff as possible: two very opposing goals.

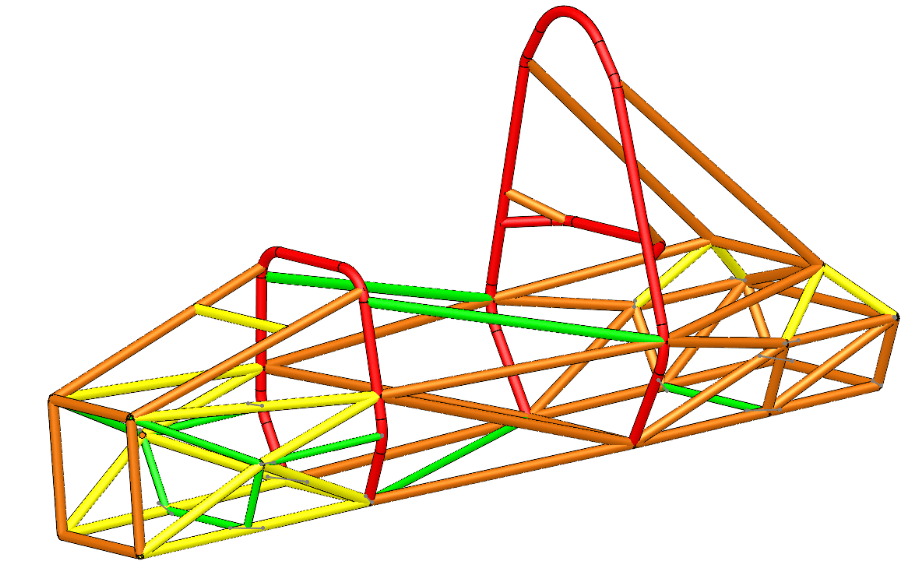

I approached the stiffness problem by developing a beam model of our spaceframe and running a modal analysis. While not the most accurate, it allowed for rapid iteration to see which tubes and wall thicknesses provided the most stiffness.

From there, I developed an analysis spreadsheet comparing the relative stiffness per kilogram of mass each tube adds to converge on a final chassis configuration. Lastly, I developed a suspension model in Ansys to estimate the torsional stiffness of the chassis.

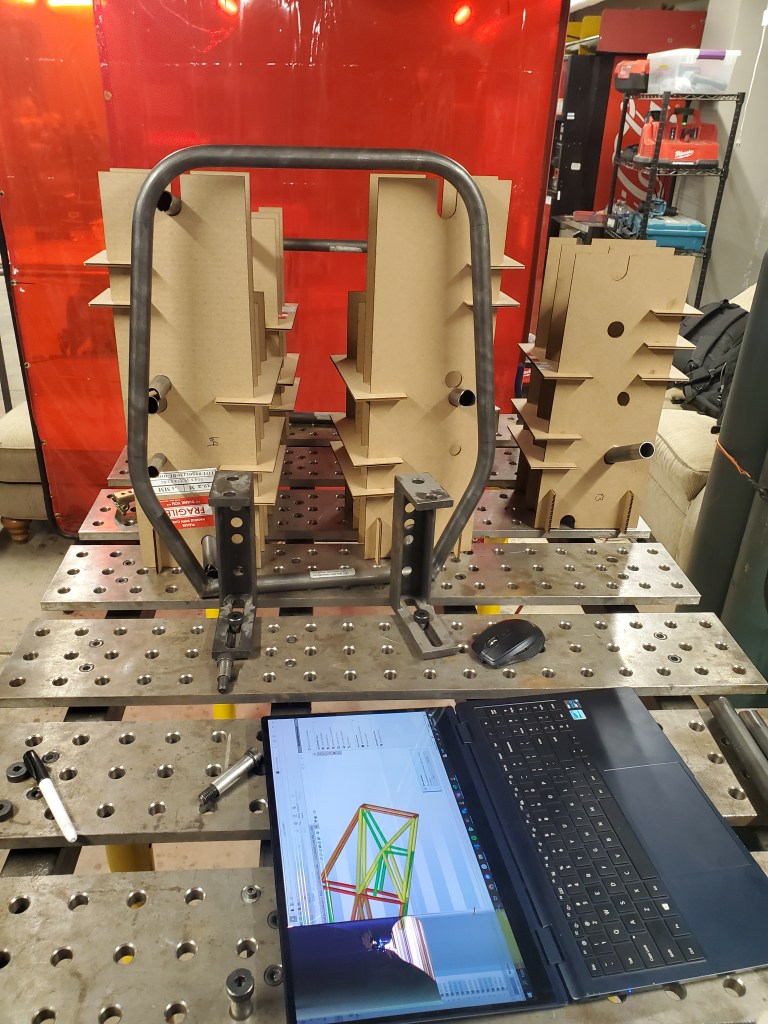

However, simulations are useless without any verification. As such I developed a torsional stiffness jig to confirm the results of chassis stiffness, which was incredibly close to the simulated result(1836Nm/deg simulated vs 1786Nm/deg measured)

Fully Welded Chassis

Chassis In CAD

Chassis Torsional Stiffness Rig

Full FEA Model with Suspension

Comparative Analysis of chassis tube configuration