Powertrain Manager+ Brakes System Lead

2020-Present

For our 2022 car, I was in charge of the powertrain subsystem. This meant that I was in charge of coordinating integration between the car’s uprights, cooling, brakes, gearset, and hubs. I led high-level team design decisions such as the implementation and research of dynamic seals, along with contacting machine shops and producing drawings to verify machinability and design for manufacturing.

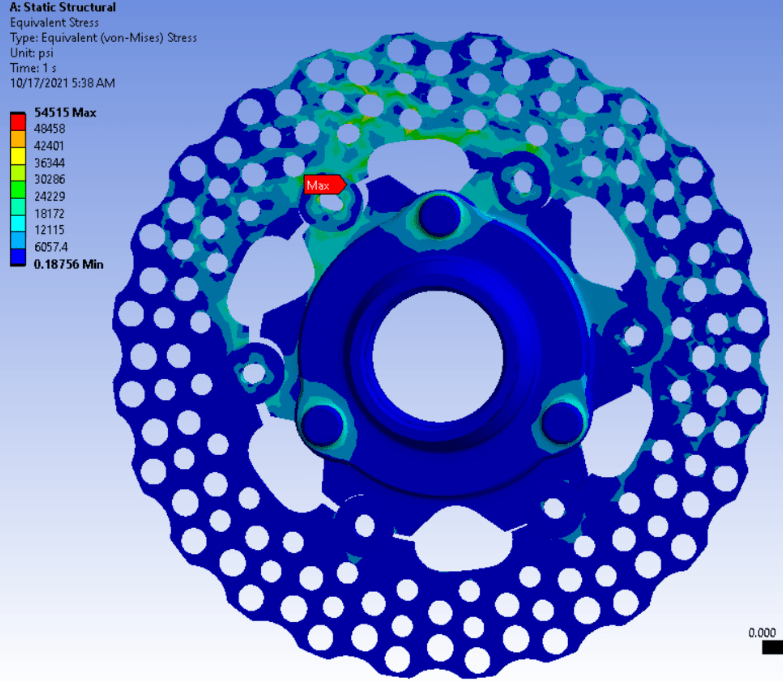

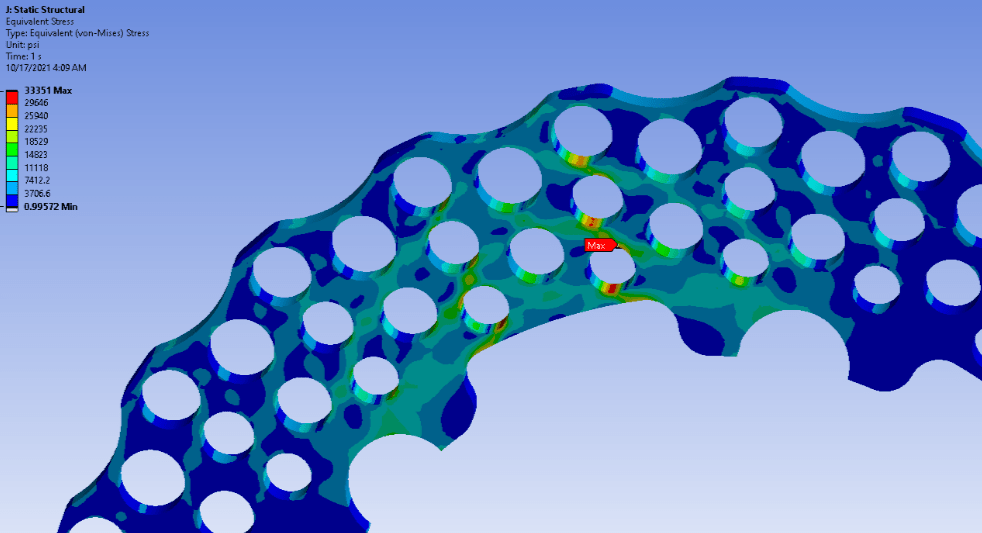

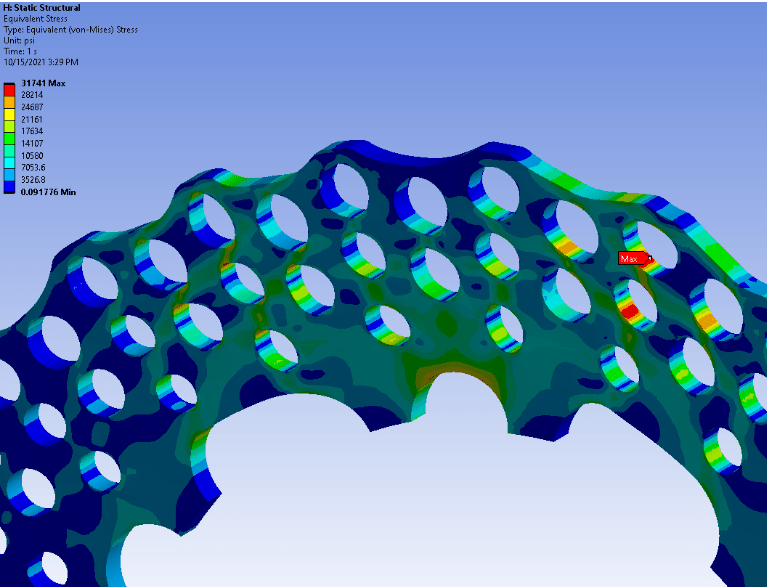

For the Brakes system in particular, I had to analyze car forces along with the weight transfer included when braking. From there, I would determine the maximum forces rotors see, and design rotors that minimize mass while maintaining rigidity. This is done through Ansys Mechanical static structural simulations. I would iterate across designs in order to determine an optimal hole pattern. Note how the rear has larger holes than the front. This is due to the rear rotors seeing lower forces due to a 2 piston caliper vs. a 4 piston caliper in the front. This discrepancy in pistons is due to the weight transfer of the car under a braking scenario.

I used a drilled hole design in order to maximize cooling, as I would perform a transient thermal analysis based on the heat flux I had calculated going into each rotor.

I had also performed analysis of the rotor buttons that allow for a free-floating design in Ansys Mechanical

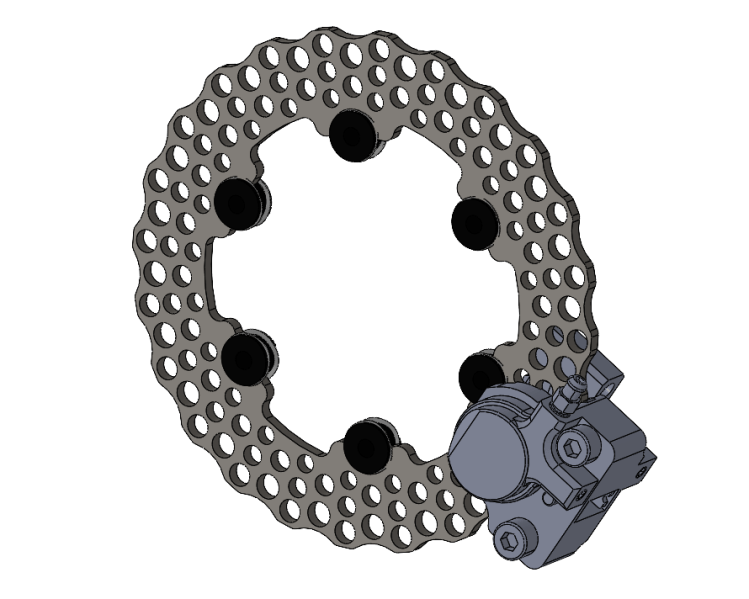

Rear Rotor assembly

Front Rotor Assembly

Full Hub+Rotor+Rotor Button Analysis

FEA of Rear rotor

FEA of Front Rotor

Brake rotor temperatures after 1 decelration

Brake Rotors reaching a maximum steady-state temperature in a worst-case braking scenario

Manufacturing of Rotor in CNC